|

|

|

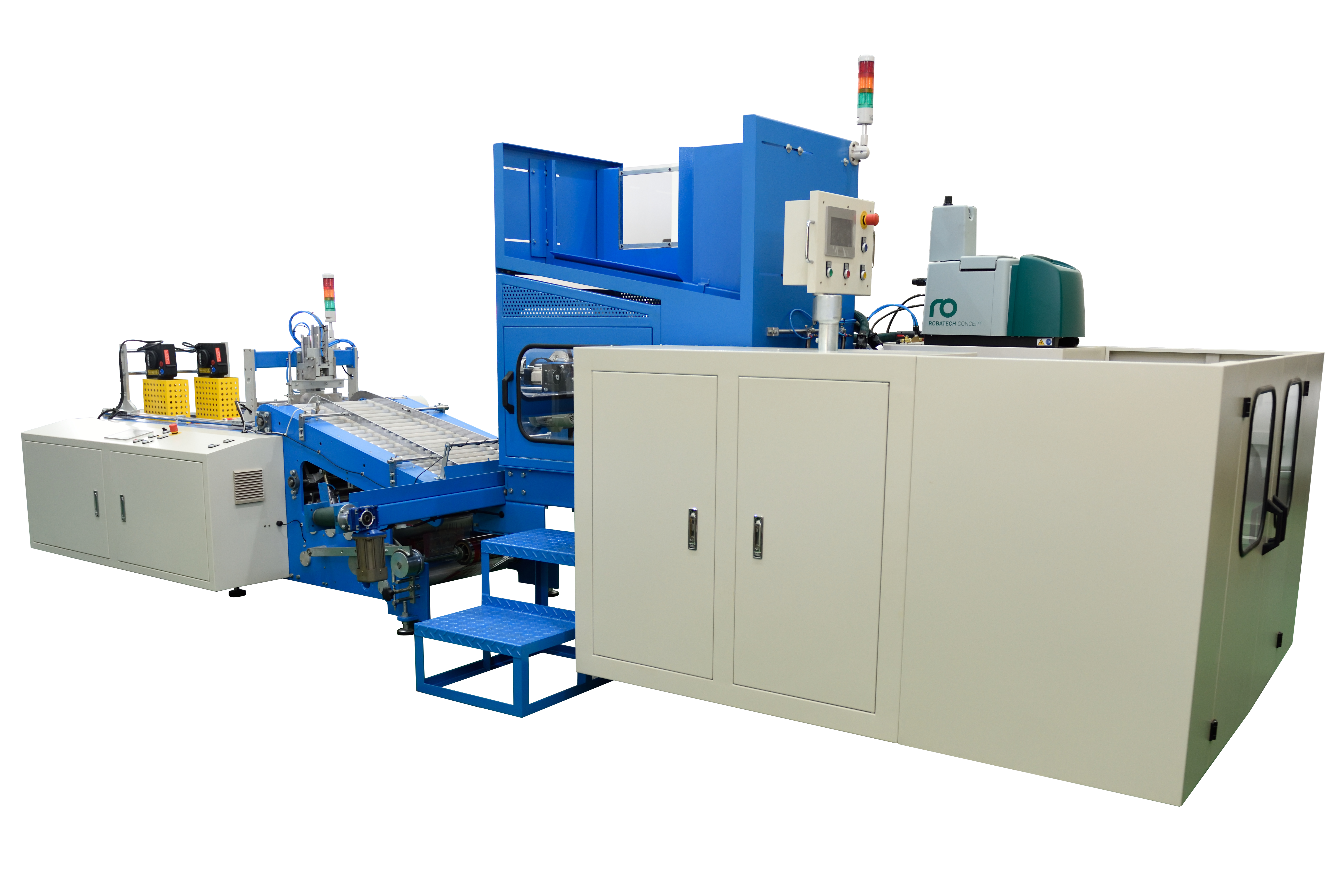

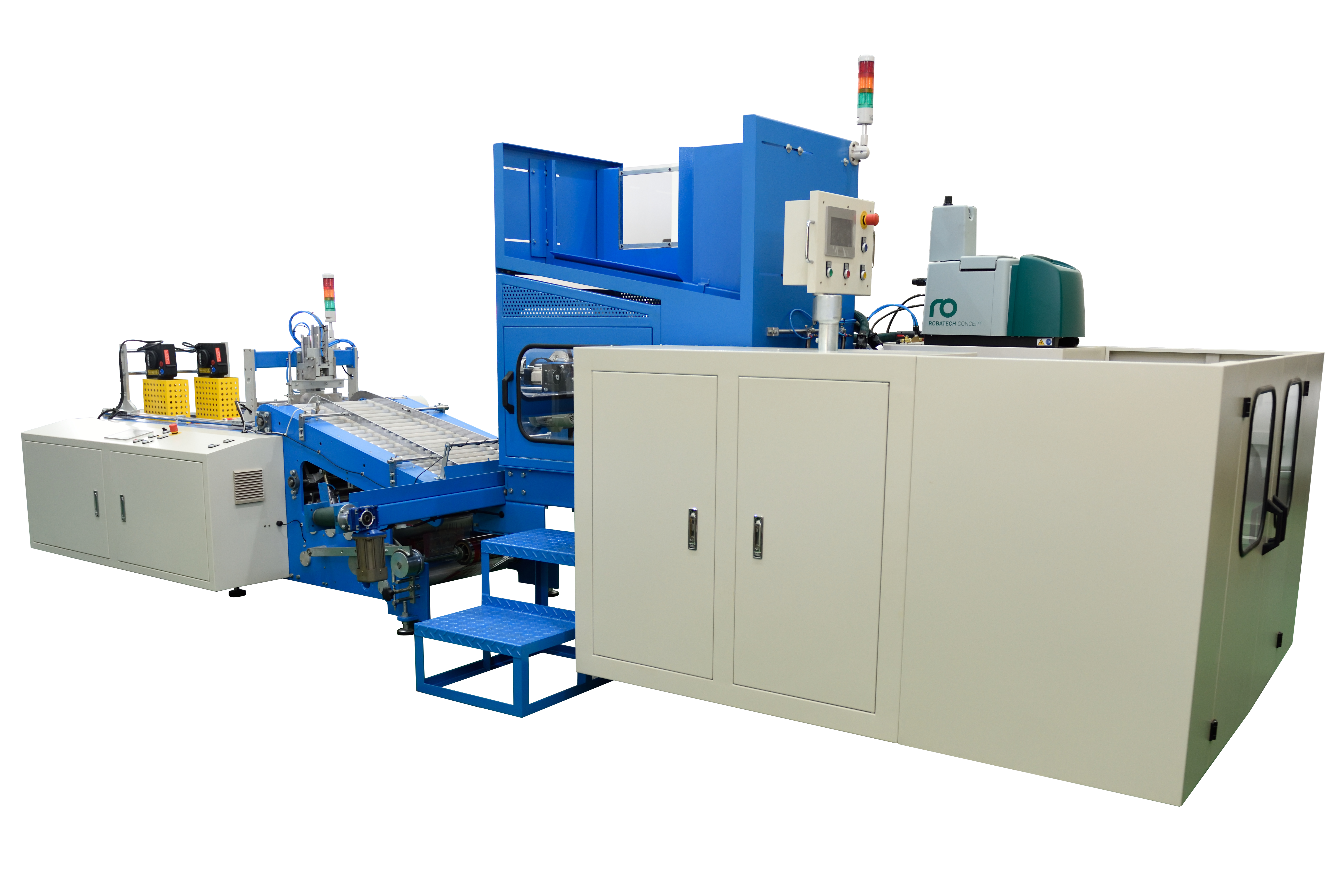

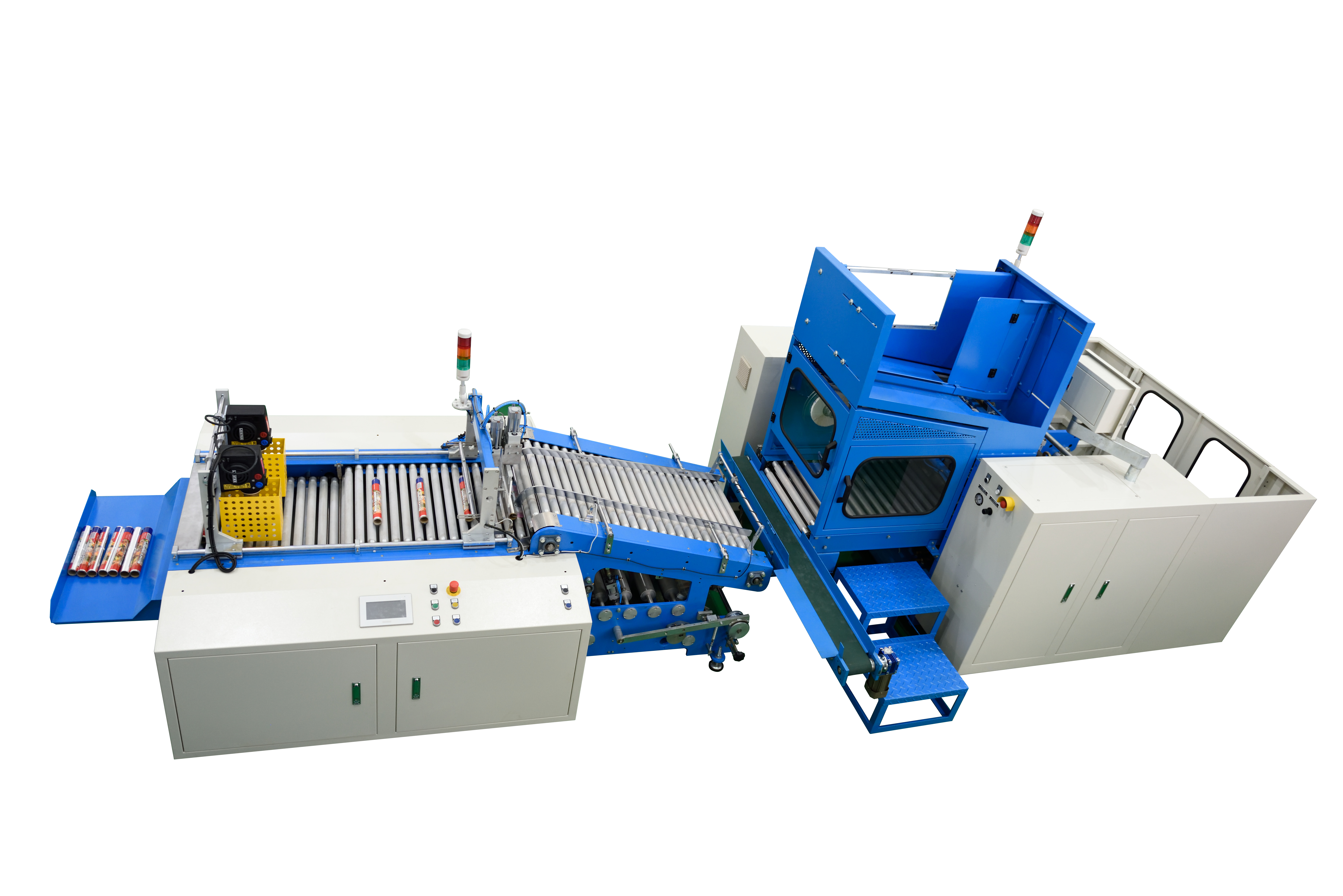

| NORDOSN Hot melt | labelling system | Hot-air system |

DESCRIPTION

AH-6S connected to TPG 50, the fully automatic production line, fully automatic operation system.

Use a conveyor to combine two models for manufacture.

Machine will automatically rewind material after input paper core.

When the roll is finished and unloaded, it is carried to the packing area for automatic packing process.

If the packing function is not used temporarily, TPG50 can be switched to delivery mode.

Or use the conveyor which connects 2 machines to unload products from the side.

This production line achieves automated manufacture.

It saves time and manpower of moving materials and rolls from machine to machine.

TRU-BRUTE Machinery always provides the beneficial collocation of machine for you.

Welcome to consult machine with us. We will at your service.

| Model | AH-6S(250-450) | AH-6S(300-500) |

| Raw Material | Aluminum foil / PE.PVC food wrapping film | Capacity (On the basis of foil roll’s length within 10 meters) |

30rolls/min |

| Mother roll core inner diameter (I.D.) | 3” (76 mm)/6"(152mm) | |

| Max mother roll diameter | 700mm | |

| Mother roll available width | 250 - 450 mm | 300 - 500 mm |

| Material thickness | 9 - 20 micron | |

| Length of the finished rolls | 3 - 250 Meter | |

| Max finished roll's diameter | 80 mm | |

| Finished paper core Length | 255 - 470 mm | 305 - 520 mm |

| Max finished roll's paper core diameter | 50mm | |

| Finished paper cores inner diameter (I.D.) | 25 - 38 mm | |

| Pressure of compressed air system | 8±2atm | |

| power supply | AC220/380/415/440V,50Hz/60Hz,3PH | |

| Max power consumption | 7.0 KW(no glue) 11kw(glue) | |

| Dimensions L x Wx H | 2450 x 2100 x 2000 mm | |

| Net weight | 2100 kg | |

| Type of film | Shrink film |

| Shrink film inner core diameter | 3” (76mm) |

| Shrink film width | 305 - 505 mm |

| Shrink film thickness | 20 micron |

| Shrink film outer diameter | 300 mm |

| Outer wrapping film length | 170 - 185 mm |

| Semi-finished product outer diameter | 30 - 45 mm |

| Semi-finished product width | 300 - 470 mm (Max.) |

| Mechanical productivity | 20 rolls/min. (Max.) |

| Installed power | 7 KW |

| Power supply | 220V, 50Hz, 3ph |

| Dimensions L x W x H | 2800 x 1950 x 1800 mm |

| Net weight | 2500 kg |